Trending...

- Attn: Newspapers: EXTRA! EXTRA! Read all about it! Get in on Giant New Advertising Revenues NOW!

- PR Support That Cuts the Mustard for Busy Founders

- California: Governor Newsom announces appointments 12.30.2025

Kaltra's new one-piece manifold technology removes former limits of large microchannel water coils, enhancing reliability for data centers, AHUs, and free cooling systems.

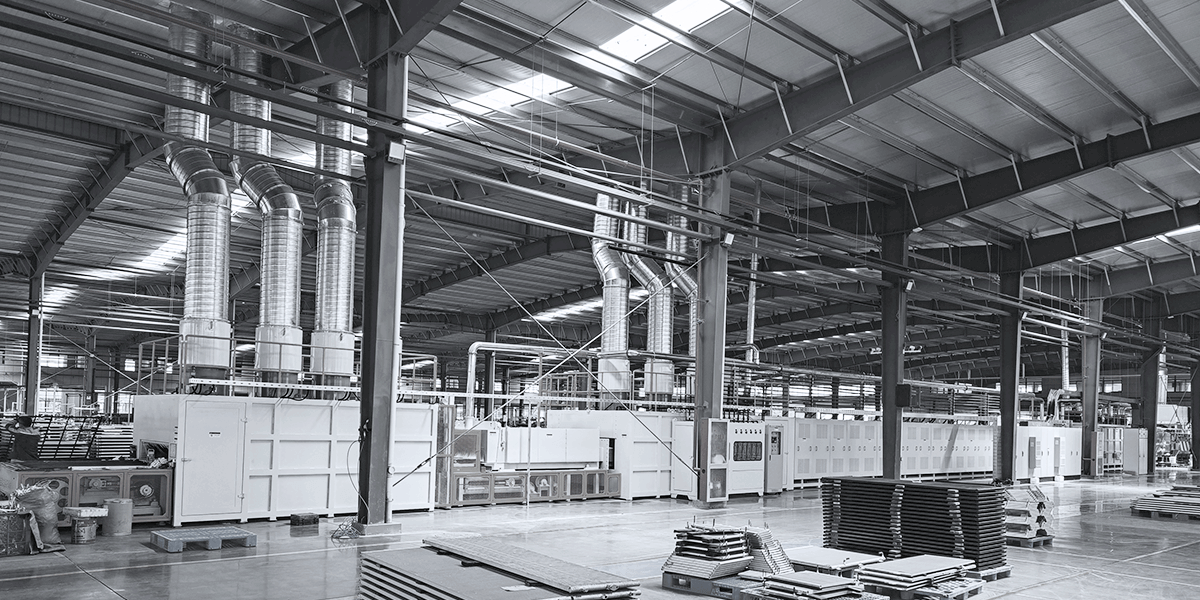

ALTMUNSTER, Austria - Californer -- With the commissioning of a fully automated tube-processing station capable of cutting and punching the complete range of manifold tubes up to 2400 mm in length, Kaltra can now supply microchannel coils equipped with solid, one-piece manifolds. This capability is particularly valuable for large microchannel water coils, where seamless manifolds significantly increase structural robustness, reduce assembly time, and lower overall production cost.

Beyond manufacturing efficiency, one-piece manifolds offer notable engineering advantages. By eliminating welded joints along the manifold length, the risk of leakage is reduced, pressure integrity is improved, and long-term reliability is enhanced.

More on The Californer

The launch of the tube-processing station represents the final step in Kaltra's transition to a fully integrated production line for large microchannel coils. Earlier, the company expanded its manufacturing capabilities by installing large-conveyor CAB furnaces, enabling reliable brazing of oversized heat exchangers and paving the way for large-MCHE production.

Historically, large-format microchannel water coils faced constraints in demanding environments—especially in data center applications, where they are used as AHU coils and free cooling coils, and where absolute reliability is essential. With the introduction of solid, one-piece manifolds and full-scale large-MCHE production technology, these limitations have now been fully removed.

As a result, Kaltra's customers gain access to a new class of high-capacity, highly reliable microchannel fluid coils suitable for the most demanding and mission-critical cooling applications.

To date, Kaltra provides the widest nomenclature of tubes and components for microchannel water coils among all manufacturers. This allows the company to deliver tailored solutions that precisely match OEM requirements, ensuring optimal thermal performance, reliability, and integration across diverse applications.

Beyond manufacturing efficiency, one-piece manifolds offer notable engineering advantages. By eliminating welded joints along the manifold length, the risk of leakage is reduced, pressure integrity is improved, and long-term reliability is enhanced.

More on The Californer

- Dr. Dawson Church's Spiritual Intelligence Wins Gold in Two Categories

- Anne Seidman: Within the Lines

- Kill the Ego. Elevate Your Game

- How Democrats Made Healthcare More Expensive in 2026

- Fun And Easy Health Introduces DPMN Renew as a New Nervous System Support Offered in Murrieta, Ca

The launch of the tube-processing station represents the final step in Kaltra's transition to a fully integrated production line for large microchannel coils. Earlier, the company expanded its manufacturing capabilities by installing large-conveyor CAB furnaces, enabling reliable brazing of oversized heat exchangers and paving the way for large-MCHE production.

Historically, large-format microchannel water coils faced constraints in demanding environments—especially in data center applications, where they are used as AHU coils and free cooling coils, and where absolute reliability is essential. With the introduction of solid, one-piece manifolds and full-scale large-MCHE production technology, these limitations have now been fully removed.

As a result, Kaltra's customers gain access to a new class of high-capacity, highly reliable microchannel fluid coils suitable for the most demanding and mission-critical cooling applications.

To date, Kaltra provides the widest nomenclature of tubes and components for microchannel water coils among all manufacturers. This allows the company to deliver tailored solutions that precisely match OEM requirements, ensuring optimal thermal performance, reliability, and integration across diverse applications.

Source: Kaltra GmbH

Filed Under: Business

0 Comments

Latest on The Californer

- Domenic Migliore Releases New Short Story Collection, Frame Story

- JS Gallery Brings Global Voices to LA Art Show 2026 with "OFF SCRIPT" Exhibition

- Airiodion Group Named a Top Boutique Change Management Consulting Firm

- ANTOANETTA Partners With Zestacor Digital Marketing to Expand Online Presence for Handcrafted Luxury Jewelry

- Cheap Car Wash Near California State University Northridge

- California: Governor Newsom announces appointments 1.2.2026

- 11 Wins, Limitless Impact: 2025 Viddy Awards Honor Scientology Media Productions

- Car Wash in Northridge Near CSUN

- Marc Yaffee Comes To Stubby's Cool January 17

- Website Traffic Generator – GA4 Tracking

- Introducing "Like A Virgin" — A New Bridal Brand for the Modern, Untraditional Bride

- FrostSkin Launches Kickstarter Campaign for Patent-Pending Instant-Chill Water Purification Bottle

- The New Monaco of the South (of Italy)

- Mike Diamond Launches Free Sewer Camera Inspection Offer in Los Angeles

- ExecLayer Launches Patent-Pending Generative Ops Platform for Enterprise Operations

- Nine Years On, Still Incredible: Lightning Motorcycles Defies EV Obsolescence

- Reinforcement Learning Accelerates Model-free Training of Optical AI Systems

- Melospeech Reports 96% of Therapy Goals Met, Exceeded, or Showing Meaningful Progress at Six-Month Reassessment in 2025

- Lick Personal Oils Introduces the Ultimate Valentine's Day Gift Collection for Romantic, Thoughtful Gifting

- California: Governor Newsom honors fallen CAL FIRE Engineer