Trending...

- Grammy award-winning Cuban-Canadian artist Alex Cuba releases his 11th studio album, "Indole," today

- Ofb Yung X Casey Veggies Drop "lit Shit" — A West Coast Banger

- California: Paw and order: four new K-9 teams join CHP to increase public safety statewide

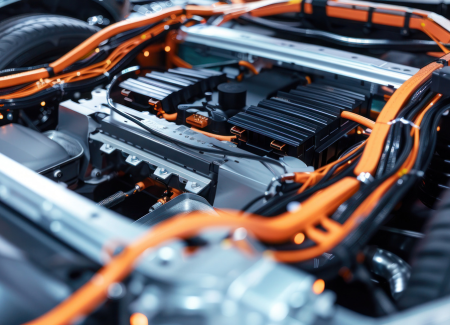

DALLAS, N.C. - Californer -- Discover how one formulation enables cost-efficient, sustainable ESD packaging for the automotive industry without compromising performance.

Background

A leading German-based packaging manufacturer serving the automotive industry sought to enhance its offering of electrostatic discharge (ESD) safe polypropylene (PP) boxes used by major OEMs. The company had previously outsourced production but recently invested in its own production facility, signaling a strategic move toward expanding in-house manufacturing capacity to better serve its European customer base.

Challenge / Need

The customer was under significant cost pressure in a highly competitive market. The challenge was to meet strict ESD and mechanical performance targets while simultaneously reducing material costs and incorporating sustainable practices. The end customer—automotive OEMs—also demanded circularity and environmental compliance, adding complexity to material selection.

More on The Californer

Solution

Premix offered its conductive PRE-ELEC® compound, tailored for ESD packaging in the automotive sector. The standout feature was its ability to tolerate recycled content allowing integration of both generic and customer-specific regrind while maintaining key mechanical and conductive properties.

To verify this, dilution trials were conducted comparing the compound (0% additional regrind) with compound diluted by 10% of the customer's own regrind:

Surface Resistivity (Conductivity):

0% regrind: ~3.30E+04 Ω (excellent ESD performance)

10% regrind: 1.90E+05 Ω (still well within target conductivity range)

Impact Strength – Charpy Notched (ISO 179, +20 °C):

0% regrind: 58 kJ/m²

10% regrind: 54 kJ/m²

Impact Strength – Izod Notched (ISO 180, +20 °C):

0% regrind: 48 kJ/m²

10% regrind: 46 kJ/m²

These results demonstrated that PRE-ELEC® maintains its critical performance properties even with 10% regrind blended in—proving its robustness and suitability for circular economy applications.

More on The Californer

By enabling up to 40% (mentioned in our MSDS) regrind content in the compound and an additional 10% customer-specific regrind, Premix delivered a material solution that met both technical targets and cost efficiency goals for high-volume automotive packaging.

Results / Benefits

Cost Efficiency: The high regrind tolerance enabled significant material cost savings without compromising product quality.

Sustainability: By reusing internal waste and integrating recycled materials, the solution aligned with OEMs' sustainability goals.

Performance Assurance: Testing showed that the material retained key impact strengths despite the dilution with regrind.

The customer was highly satisfied, as Premix helped the packaging manufacturer remain competitive in a demanding market while advancing their transition toward a more circular production model.

Want to explore how Premix materials can support your packaging innovations? Contact us today at: https://www.premixgroup.com/premix-group/premix-in-the-us

Background

A leading German-based packaging manufacturer serving the automotive industry sought to enhance its offering of electrostatic discharge (ESD) safe polypropylene (PP) boxes used by major OEMs. The company had previously outsourced production but recently invested in its own production facility, signaling a strategic move toward expanding in-house manufacturing capacity to better serve its European customer base.

Challenge / Need

The customer was under significant cost pressure in a highly competitive market. The challenge was to meet strict ESD and mechanical performance targets while simultaneously reducing material costs and incorporating sustainable practices. The end customer—automotive OEMs—also demanded circularity and environmental compliance, adding complexity to material selection.

More on The Californer

- MVP Showcases Cutting-Edge AOI for Semiconductor, Packaging & Microelectronics at Productronica 2025

- International Cup 2025 Champions Innovation and Global Collaboration

- LA28 Unveils Olympic Games Competition Schedule, 161 Ticketed Events to Occur in Long Beach

- Allen Field Co., Inc. Components Selected for Esko ArtiosCAD 3D Component Library

- California: Governor Newsom announces graduation rates and academic achievements continue improving

Solution

Premix offered its conductive PRE-ELEC® compound, tailored for ESD packaging in the automotive sector. The standout feature was its ability to tolerate recycled content allowing integration of both generic and customer-specific regrind while maintaining key mechanical and conductive properties.

To verify this, dilution trials were conducted comparing the compound (0% additional regrind) with compound diluted by 10% of the customer's own regrind:

Surface Resistivity (Conductivity):

0% regrind: ~3.30E+04 Ω (excellent ESD performance)

10% regrind: 1.90E+05 Ω (still well within target conductivity range)

Impact Strength – Charpy Notched (ISO 179, +20 °C):

0% regrind: 58 kJ/m²

10% regrind: 54 kJ/m²

Impact Strength – Izod Notched (ISO 180, +20 °C):

0% regrind: 48 kJ/m²

10% regrind: 46 kJ/m²

These results demonstrated that PRE-ELEC® maintains its critical performance properties even with 10% regrind blended in—proving its robustness and suitability for circular economy applications.

More on The Californer

- Thirteen Reasons Why Gyminny Kids Is San Diego's Best Gymnastics Gym

- Governor Newsom announces California's record growth in battery storage and clean energy leadership at COP30

- Governor Newsom pre-deploys emergency resources to Southern California ahead of storms

- California cuts major methane leaks as Trump turns his back on science

- Heritage At Manalapan - A New Luxury Single Family Home Community Coming Late 2025

By enabling up to 40% (mentioned in our MSDS) regrind content in the compound and an additional 10% customer-specific regrind, Premix delivered a material solution that met both technical targets and cost efficiency goals for high-volume automotive packaging.

Results / Benefits

Cost Efficiency: The high regrind tolerance enabled significant material cost savings without compromising product quality.

Sustainability: By reusing internal waste and integrating recycled materials, the solution aligned with OEMs' sustainability goals.

Performance Assurance: Testing showed that the material retained key impact strengths despite the dilution with regrind.

The customer was highly satisfied, as Premix helped the packaging manufacturer remain competitive in a demanding market while advancing their transition toward a more circular production model.

Want to explore how Premix materials can support your packaging innovations? Contact us today at: https://www.premixgroup.com/premix-group/premix-in-the-us

Source: Premix

Filed Under: Automotive

0 Comments

Latest on The Californer

- 16th Annual Zed Fest Film Festival 2025 Opens Nov 11, 2025 Regal Cinemas Noho West

- U.S. Military to Benefit from Drone Tech Agreement with NovaSpark Energy, Plus Longer NASA Space Missions via Solar Power Leader: Ascent Solar $ASTI

- The Great Junk Hunt is back in Orange County – Come Be Inspired by This Amazing Vintage Market!

- The Great Junk Hunt Makes its Bay Area Debut– Come Be Inspired by This Amazing Vintage Market!

- $76 Million in Gold & Silver Holdings and Expanding Production — Pioneering the Future of Gold: Asia Broadband Inc. (Stock Symbol: AABB) is Surging

- Actress Saila Rachelle is now adding Sports Advisor

- Wohler announces three SRT monitoring enhancements for its iVAM2-MPEG monitor and the addition of front panel PID selection of A/V/subtitle streams

- Schemawriter.ai launches WordPress plugin as industry leaders confirm - schema markup is critical

- 20 Million Financing to Accelerate Growth and Advance Digital Asset Strategy Secured for Super League (N A S D A Q: SLE)

- uCAR Trading Launches goldsilbermarkt.de, a New Online Shop for Precious Metals

- Webinar Announcement: Reputational Risk Management in Internal Investigations: Controlling the Narrative Before, During, and After a Crisis

- Taking on the Multi-Billion-Dollar Swipe Industry: AI Curates Who You Meet—IRL over brunch

- Marginalized Voices Rise in Right to Harm on Documentary Showcase

- California: Governor Newsom inks new global partnerships at COP30 as Trump administration doesn't even show up

- North America Channel Alliance Gathers Momentum

- Royal Concrete Works Launches Site: Expert LA Concrete Services

- Long Beach Airport Cuts Carbon Emissions by 56%, Renews Sustainability Accreditation

- 5,000 Australians Call for Clarity: NaturismRE's Petition Reaches Major Milestone

- Redefining Real Estate in the Bay Area

- ARC Raiders Guide – How To Beat The Queen, The Hardest Boss In The Game